Image source: Car.co.za

The development focus of BBA is shifting to the electric vehicle market.

Recently, the top three German luxury cars have accelerated their electrification transformation in unison.

On November 11, BMW took the lead in unveiling the BMW iNEXT mass-produced model BMW iX at the 2020 "BMW Group #NEXTGen Future Summit", adding another corner to the pure electric camp.

Audi also began to "spend money to bet on the future." On December 3, Audi increased its investment in electrification and announced a total investment of 35 billion euros by 2025, and future technology investment will account for half of the country.

Daimler shot more generously. On December 4, Daimler announced that it will spend more than 70 billion euros on research and development, real estate, plant and equipment between 2021 and 2025, with the focus of investment on "electrification and digitalization."

The heavy investment in electrification reveals the powerlessness and urgency of BBA in the electric vehicle market. According to EV Sales data, from January to October 2020, Tesla sold a total of 352,700 electric vehicles worldwide. BMW, Mercedes-Benz and Audi sold 116,900, 89,600 and 74,300 respectively, one of the three BBA sales. And neither can compare to Tesla.

This time the BBA is betting heavily on electrification, where is the money going?

How fragrant is the exclusive electric vehicle platform?

Exclusive electric vehicle platform is the direction of BBA's massive investment.

Previously, traditional car companies were somewhat conservative when developing electric models. Due to the uncertainty of the "global electrification process", traditional car companies do not want to miss opportunities, and lack the courage of new forces to dare to try and make mistakes. Therefore, initially, BBA adopted a more conservative "oil-to-electricity" approach.

But in fact, "oil-to-electricity" has many natural defects.

For electric vehicles, cruising range is an important parameter, which mainly depends on battery capacity and energy efficiency. The fuel truck platform does not reserve space for the battery. The battery packs added later can only be inserted into the car with pins and needles, and the available capacity is very limited. In addition, in order to match the frame of a fuel vehicle, it is necessary to add a brand new electric structure to the already formed mechanical space. In short, "oil-to-electricity" products have a small number of batteries and a heavy vehicle, so the endurance level is naturally difficult to improve.

Therefore, the sales of electric models launched by BBA in the early stage were mediocre. After the "Zheji" electrification, BBA finally reached an agreement to build an exclusive platform for electric vehicles.

In the third quarter earnings report, BMW Group Chairman Oliver Zipse confirmed that the new electric vehicle platform will be put into production at the new plant in Hungary after 2025. Audi has taken the lead. The Audi Q4 e-tron is built on the Volkswagen MEB platform. In addition, the PPE platform, a high-end electric vehicle platform jointly developed by Audi and Porsche for large electric vehicles, will also be introduced into the country. The first model is scheduled to be put into production in 2024. Mercedes-Benz also stated that it will launch two dedicated platforms (architectures) for electric vehicles.

Source: Mercedes-Benz official

The pure electric platform that is being developed forward has been forward-looking design based on the characteristics of electric vehicles. For example, proper space is reserved for batteries and motors, so that batteries, electronic controls, and motors can be integrated, so that electric vehicles have longer battery life and performance Better.

The technical improvement can be seen from the battery life of the first model built by BBA based on the pure electric platform. Under WLTP conditions, Mercedes-Benz's EQS model built on the EVA platform has a cruising range of 700 kilometers; the BMW iNext model has a cruising range of 579 kilometers.

In addition, the pure electric platform also has the characteristics of lighter weight and better rigidity of the whole vehicle, a safer battery protection system, and a lower and more even distribution of the center of gravity of the vehicle body. The driving texture is much better than that of gasoline-electric vehicles. Promote.

The attitude towards the development of an exclusive platform for electric vehicles shows that electrification has become a general trend, and BBA no longer bears the pressure of "uncertainty".

However, the development cost of a pure electric platform is a huge expense. According to Volkswagen, its research and development of the MEB modular electric architecture cost 7 billion euros. To recover the cost of developing the MEB platform requires the sale of 20 million electric vehicles, which is expected to be achieved in 2029. For the BBA, which sells about 2 million vehicles a year, it may be far away from cost recovery.

"Hold the battery in your hand"

In addition to the exclusive platform for electric vehicles, BBA has extended its reach to the field of power batteries, demonstrating its great determination to compete in the electric vehicle market.

Power batteries are the core component of electric vehicles. With the increase in sales of electric vehicles, insufficient supply of power batteries often occurs. BBA has also suffered losses due to battery supplier capacity issues.

In March 2019, due to the inability to obtain enough batteries from LG Chem, Audi’s pure electric vehicle plant reduced its production capacity in 2019 from 55,800 to 45,200. Mercedes-Benz has also postponed the delivery plan of its first pure electric SUV model EQC due to insufficient power battery supply.

The CEO of Volkswagen Group Herbert Diss once stated that the annual sales of Volkswagen Group's electric vehicles in China will reach 1.5 million, and the demand for power batteries will reach 75GWh. The CATL Annual Report shows that in 2019, the global power battery leader Ningde The production capacity of the times is only 53GWh.

Power battery giant Samsung SDI has also undertaken orders from Daimler, BMW, Volkswagen and other car companies, and its production capacity has been stretched. In the supply agreement with Volkswagen, Samsung SDI had planned to supply 20GWh power batteries to Volkswagen, but in the end, limited by production capacity, Volkswagen only received 5GWh power batteries.

Therefore, it is extremely important to keep the battery in your own hands. BBA also chose to control the "battery destiny" by itself.

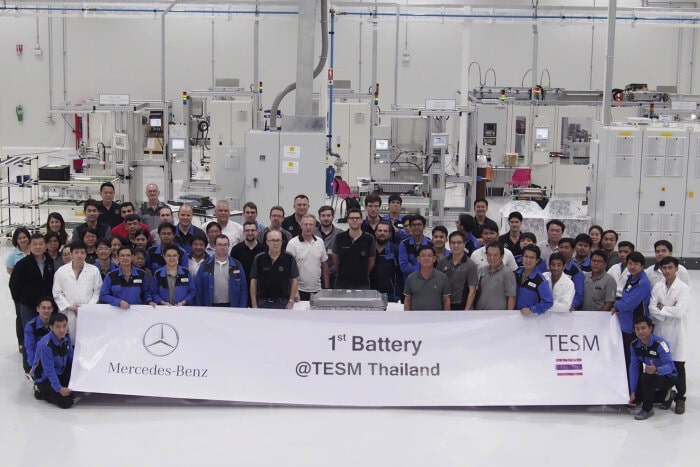

At present, Mercedes-Benz owns or is building 9 battery factories in Europe, Asia, and North America, and merges with Funeng Technology; Audi will establish a battery assembly plant near the Ingolstadt plant, and will jointly develop batteries with BYD; BMW The United States, Germany, China and Thailand have 4 battery factories.

Mercedes-Benz Thailand battery plant Source: Daimler official

As the "heart" of electric vehicles, batteries account for nearly half of the cost of vehicle manufacturing. Self-built battery factories, in addition to no longer constraining production capacity, can also significantly reduce battery costs. At the same time, grasping the initiative in battery research and development can also improve the fit between batteries and electric vehicles.

However, self-built battery factories by car companies are also facing considerable risks. First, the input cost of the battery factory is high. The head of BYD Wang Chuanfu once said that a power battery plant that meets the demand for the same number of new energy vehicles installed is about twice the cost of a car factory, and the construction time of the factory is longer than that of a car factory.

At present, the road to electrification of BBA is a bit slow, but it is not without chance. The technical strength and brand appeal accumulated by BBA in the fuel vehicle market will become a strong backing for its move to the electric vehicle market. If BBA takes a major attack with pure electric platform products, the electric vehicle market may usher in a reshuffle.

AMS2024 Exhibition Guide | Comprehensive Exhibition Guide, Don't Miss the Exciting Events Online and Offline

Notice on Holding the Rui'an Promotion Conference for the 2025 China (Rui'an) International Automobile and Motorcycle Parts Exhibition

On September 5th, we invite you to join us at the Wenzhou Auto Parts Exhibition on a journey to trace the origin of the Auto Parts City, as per the invitation from the purchaser!

Hot Booking | AAPEX 2024- Professional Exhibition Channel for Entering the North American Auto Parts Market

The wind is just right, Qianchuan Hui! Looking forward to working with you at the 2024 Wenzhou Auto Parts Exhibition and composing a new chapter!

Live up to Shaohua | Wenzhou Auto Parts Exhibition, these wonderful moments are worth remembering!

Free support line!

Email Support!

Working Days/Hours!