In recent years, the automobile industry has set off a wave of electrification. With the strong support of the government and the transformation of industrial technology, new energy vehicles have entered the stage of rapid development of marketization, and also put forward higher requirements for key parts of new energy vehicles.

Since last year, the sales volume of electric vehicles in China has been growing rapidly at an annual growth rate of more than 100%. However, a close look at the new energy vehicle market can reveal some problems:

1、 The new energy vehicle market presents a trend of small size at both ends and large size in the middle: the market share of high-end and economy models is excellent, and the mid-range models are facing greater competitive pressure.

2、 In order to solve the two major pain points of longer driving distance and shorter charging time of electric vehicles, 800V high-voltage charging, integration and other solutions have come out one after another, but these solutions still have some difficulties at the key nodes of implementation.

Innovation and solutions of Sensata Technology in the field of electrification

Sensata Technology is committed to helping the industry continuously break the upper limit of electric vehicle mileage, solve the problems of slow charging of electric vehicles, and continue to innovate in the field of electrification. At present, Sensata Technology has successfully completed the development of 800V, 400A large current contactors and has been widely used in vehicles with fast charging requirements. At the same time, in order to improve the safety of high voltage and high current system, Sensata Technology also provides active and passive integrated fuses and active insulation detection equipment to ensure the safety of vehicles and personnel in all aspects before and during charging.

In view of the problem of shortening the life span in winter, Sensata Technology has developed a pressure and temperature integrated sensor specially applied to the heat pump system, which can effectively simplify the system design, reduce the system cost, and improve the system efficiency.

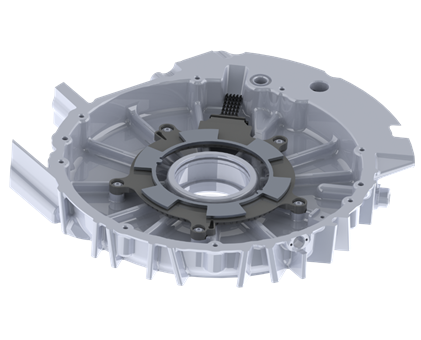

Motor is the main power source of electric vehicles. Facing the motor system, in order to assist the motor to achieve the technical goals of lightweight, multi-gear and oil cooling, Sensata Technology has also introduced the oil pressure sensor, oil temperature and pressure sensor, and motor position sensor of the shift mechanism to help improve the efficiency of the motor and the range of the whole vehicle.

Technical advantages of Sensata Technology motor rotor position sensor

At present, new energy vehicles on the market are driven by electric motors. According to the different structure and positioning, each vehicle is equipped with 1-3 motors. More than 95% of these motors are permanent magnet synchronous motors. It is necessary to accurately control the synchronization of the phase of the alternating magnetic field and the rotation of the rotor magnetic steel, which puts forward a relatively high demand for the power density and efficiency of the whole vehicle motor. For motors, the accuracy of rotor detection and rotor position is required. The motor rotor position sensor is a product to solve this problem.

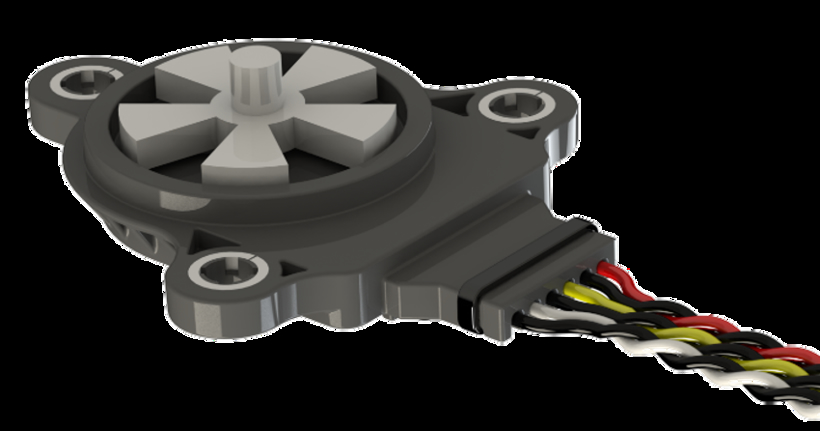

Motor rotor position sensor

The motor rotor position sensor of Sensata Technology uses 5V DC power supply and integrates partial decoding function to directly output sine and cosine signals, which is more conducive to the simplification and platformization of the controller than the rotary transformer used in traditional automobiles. The specific advantages of the motor rotor position sensor are:

● The precision is higher than that of the traditional rotation, which can effectively reduce the heat and noise of the motor and improve the efficiency of the motor.

● Higher safety, excellent anti-electromagnetic interference ability, higher signal-to-noise ratio, and avoiding misoperation caused by electromagnetic interference.

● It greatly simplifies the system design of the motor controller, thus reducing the overall cost of the system and improving the cost performance of the electric drive system.

Application advantages of Sensata technology motor rotor position sensor

Sensata Technology has been deeply engaged in the field of power train in China for more than 20 years. The motor rotor position sensor products have been pre-researched with chip suppliers since 2016, and currently has more than six years of experience in China. In China, Sensata Technology has a complete product development and verification, process development and manufacturing team, which can provide customers with comprehensive services from design, verification, simulation, functional safety development and other aspects.

Installation status of motor rotor position sensor

● From the perspective of performance, the motor rotor position sensor of Sensata Technology has shown the best performance in the bench test of each customer, and has won the praise of customers at home and abroad.

● From the perspective of supply, the motor rotor position sensor of Sensata Technology has realized the localization of the supply chain outside the chip, and there are also many certified or certified suppliers for the chip, which can ensure the product supply. In the context of the sharp increase in customer demand this year and the shortage of chips, the delivery of clients is still successfully guaranteed.

Future development trend of electric drive system

It is expected that the electric drive system will continue to improve efficiency, safety and cost-effectiveness in the future.

● Further improve the integration level of the electric drive system, thereby reducing its weight and improving its power density;

● More inclined to use more high-speed motors to reduce the overall size of the electric drive system;

● Improve the intelligent level and functional safety level of the electric drive system, and further optimize and improve the reliability of the motor.

Sensata Technology electric drive system innovation solution

The motor rotor position sensor of Sensata Technology will also exert its power on the lightweight and intelligent motor in the future. At present, Sensata Technology has been able to integrate the rotor temperature measurement on the motor rotor position sensor, thus reducing the redundancy of the motor magnetic steel, realizing the lightweight of the product, and improving the power density and cost performance.

With the continuous development of the electric drive industry, high-speed motors will gradually become popular. The speed of high-speed motors is about 20000 rpm. At such a high speed, the current at the motor shaft side will cause great corrosion to the bearings. Harmonic analysis of the motor rotor position sensor can reflect the degree of bearing wear through the change of axial movement, facilitate the maintenance of the motor, and effectively improve the safety of use.

Electric drive system plays a crucial role in the development of new energy vehicles. With the development of the new energy vehicle industry, the innovation of electric drive products and solutions becomes particularly important.

AMS2024 Exhibition Guide | Comprehensive Exhibition Guide, Don't Miss the Exciting Events Online and Offline

Notice on Holding the Rui'an Promotion Conference for the 2025 China (Rui'an) International Automobile and Motorcycle Parts Exhibition

On September 5th, we invite you to join us at the Wenzhou Auto Parts Exhibition on a journey to trace the origin of the Auto Parts City, as per the invitation from the purchaser!

Hot Booking | AAPEX 2024- Professional Exhibition Channel for Entering the North American Auto Parts Market

The wind is just right, Qianchuan Hui! Looking forward to working with you at the 2024 Wenzhou Auto Parts Exhibition and composing a new chapter!

Live up to Shaohua | Wenzhou Auto Parts Exhibition, these wonderful moments are worth remembering!

Free support line!

Email Support!

Working Days/Hours!